CASE INTRODUCTION:

In this case study we take a look at how Servato's ability to monitor temperature and detect issues such as failed fans or heat exchangers can deliver critical insight about site equipment and help extend battery life. This particular example of a failed fan illustrates how manual maintenance may have failed this site. Only a monitoring solution with constant awareness could have alerted the customer about this heat issue. Greater site insight means greater network reliability. The case walks through:

- Servato's Temperature Monitoring: How it Works

- The Site: General Overview of the Case and Site

- The Temperature Data: How ActiView was Quickly Able to Reveal Unusual Temperature Data

TEMPERATURE MONITORING:

Servato appliances are built with an Internet of Things (IoT) approach. They are designed not just to manage and monitor the State of Charge and State of Health of backup batteries, but to be aware of other environmental factors that could impact the batteries or site reliability. One such parameter often monitored by customers is ambient temperature.

Using the Servato Temperature Probe - a USB supported device with plug-and-play functionality with Servato appliances - customers can track temperature data anywhere at their site. The sensor can be placed near the batteries or other critical site equipment. Using ActiView, Servato's enterprise-class battery management software, customers can set the temperature thresholds that will trigger alerts and compare temperature data to the functioning of the rectifier and the batteries.

Figure 1: Servato Temperature Probe.

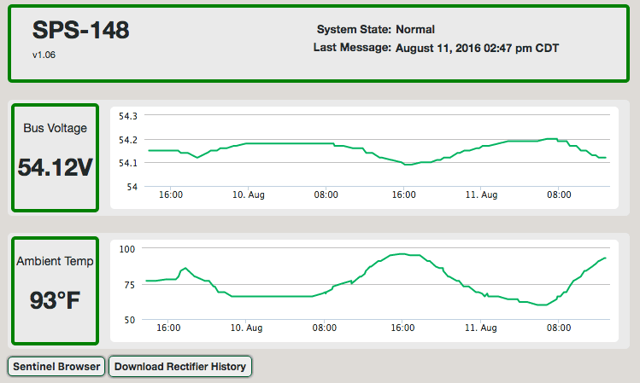

Figure 2: Sample temperature data displaying the relationship between the bus voltage and temperature at the Oregon site.

THE SITE:

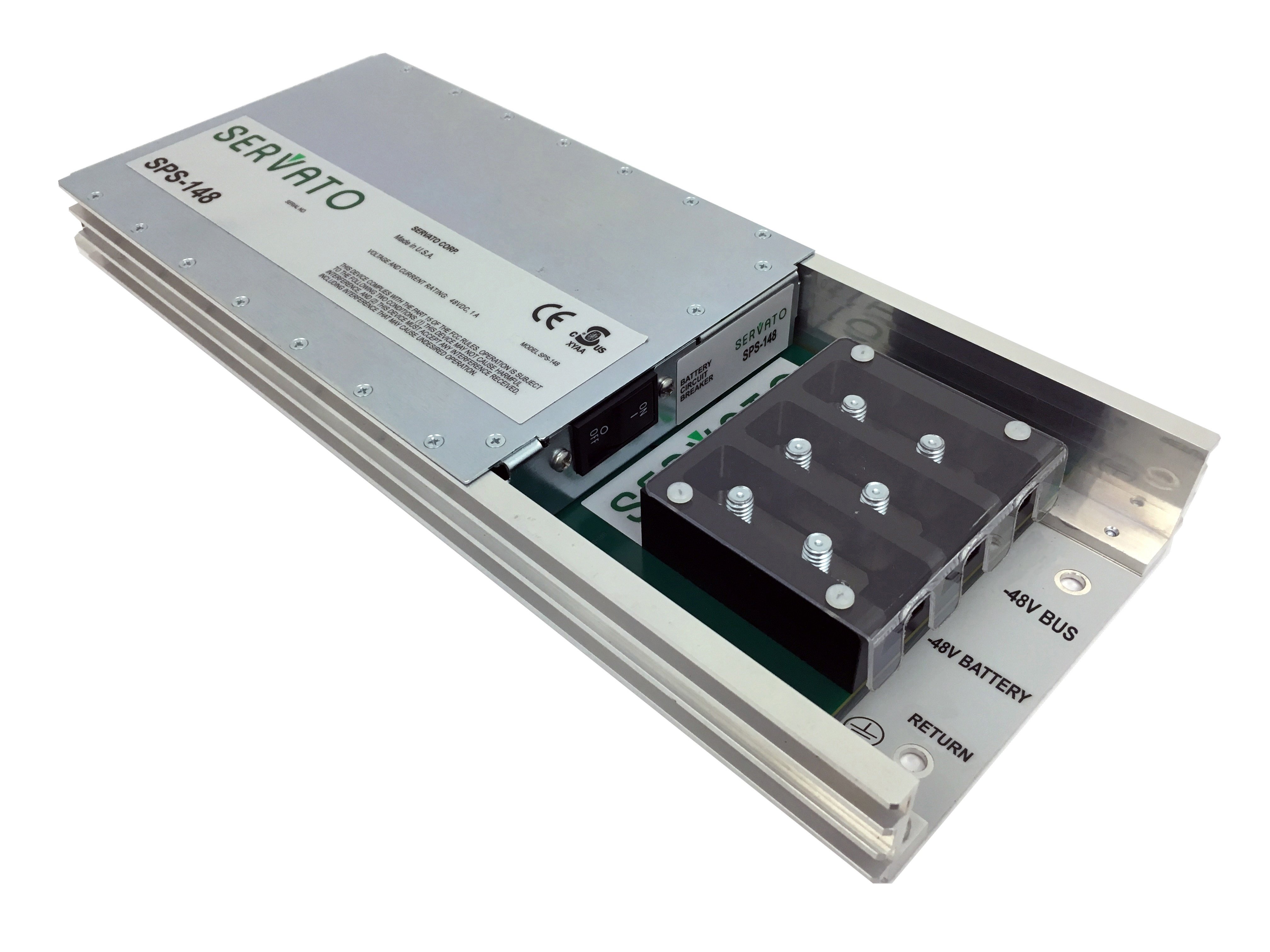

Servato installed a Smart Power System-148 (SPS-148) at a customer site in Oregon in March of 2016. A picture of the installation is shown below (Figure 3).

Figure 3: SPS-148 monitoring one string of batteries at the site in Oregon. The temperature probe is the coiled black wire resting on top of the SPS-148 device.

At the time of installation there were no known issues with the site. Cyclical maintenance performed by the customer had not noticed any equipment issues or anything noteworthy. This site had been selected as part of a FOA for Servato and data captured would be considered for further deployment.

THE DATA:

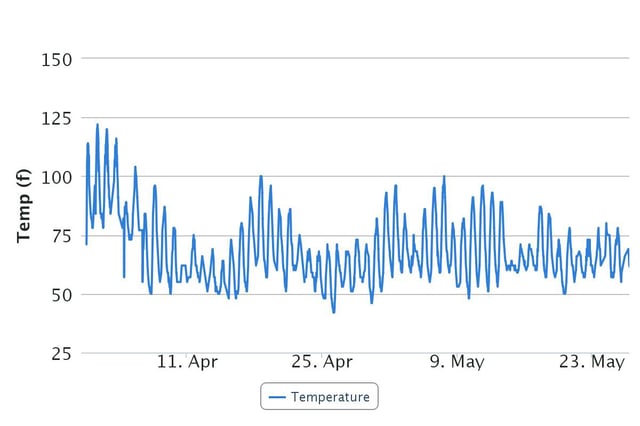

Once the SPS-148 was installed and began communicating with ActiView, the data from the temperature probe showed the customer the temperature within the cabinet. That data pointed out an obvious problem. As is visible in the chart in Figure 4, the temperature at the site was reaching above 120 degrees Fahrenheit. While this is not uncommon for OSP sites in hot parts of the United States, it was certainly unusual for a site in Oregon to be getting that hot in March.

Figure 4: Temperature data recorded in ActiView from the time of installation through May.

Technicians were sent back to the site to see if there were any issues with the fan. They discovered the fan had been miswired and thus had never worked. A simple fix later and the temperature at the site dropped dramatically, staying well below the levels initially detected even while summer rolled in and the weather warmed.

Heat generated by the batteries is the primary culprit of battery failure. More heat contributes to dry-out, grid corrosion, active material degradation, and other issues that sap batteries of their capacity. Adequate ventilation and cooling for batteries can be a problem in tightly packed cabinets, so maintaining fans and heat exchangers is critical to maintaining maximum backup power and to extending battery life.

CONCLUSION:

This simple case of detecting a bad fan via the Servato Temperature Probe illustrates just another way that Servato can generate cost savings for customers. Servato appliances apply adaptive charging to batteries, extending battery life, and make optimizing maintenance cycles and reducing truck rolls simple. But these major CapEx and OpEx savings are complimented by a wide range of other benefits such as the addition of the Temperature Probe.

Servato offers a solution for backup battery management that extends battery life and allows for advanced remote monitoring. Servato is currently working with companies in the telecom, power, transportation and solar to ensure backup power reliability through Active Battery Management